How it Works

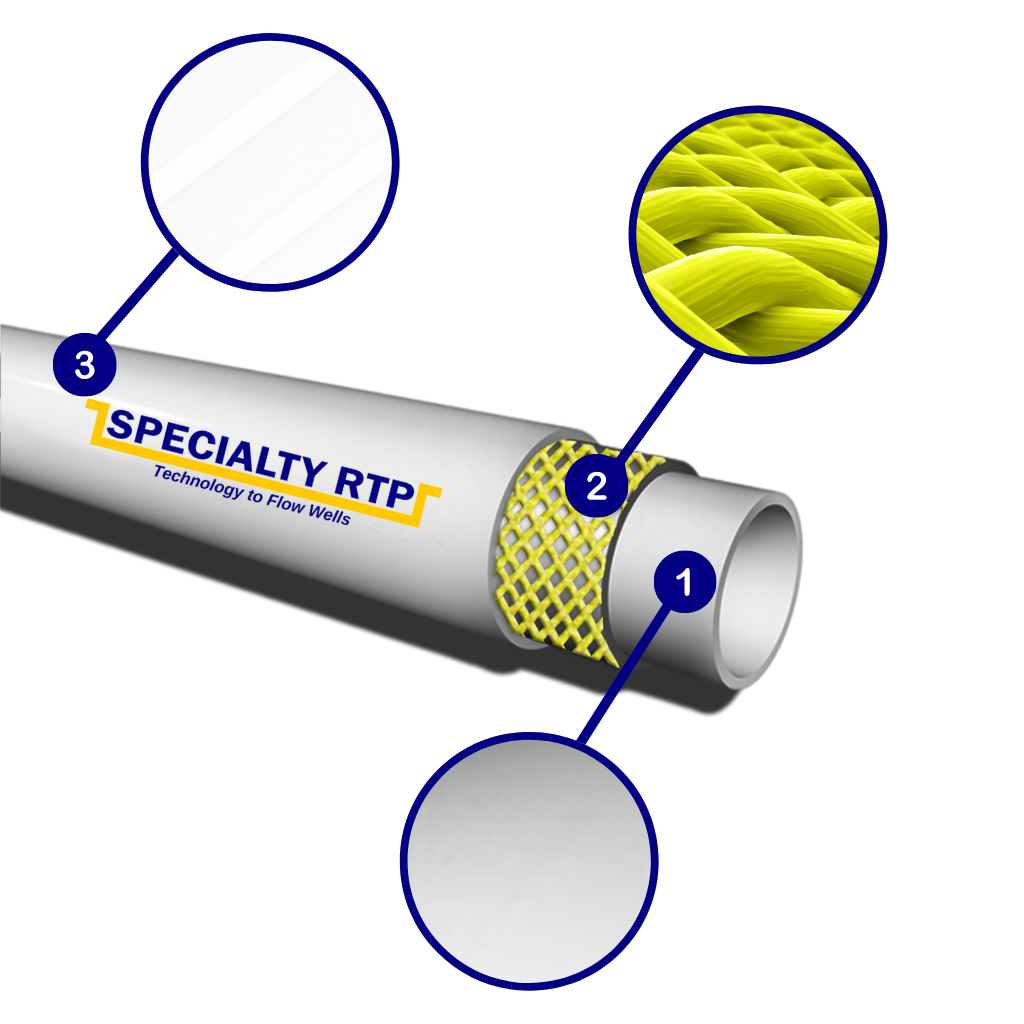

- There are three components to SRTP® Pipe: An inner liner, a reinforcement layer and an outer protective jacket.

Liner

The inner liner is designed to withstand the oilfield flowing environment without corrosion and maintain a low level of permeation. Specialty RTP utilizes various polymers depending upon the temperature, H₂S, CO₂ and Hydrocarbon concentrations. By utilizing polymers such as Polyphenylene Sulfide (PPS), Polyvinylidene Fluoride (PVDF) and Polyamide (Nylon), Specialty RTP creates pipes and tubing to withstand applications to 105°C (221°F) and any level of CO₂, H₂S, brine and hydrocarbons.

Reinforcement

Specialty RTP’s pipe and tubing strength comes from braiding aramid fibers onto the inner liner. It can create pipes with design pressures from 275PSI to 3,500PSI. Aramid fiber was chosen because of its overall strength, cyclic or fatigue benefits and chemical resistance.

outer jacket

The sole purpose of the outer jacket is to protect the reinforcement. Depending upon the application, specific polymers are employed that are resistant to the external environment.